Miniature Shock Absorbers

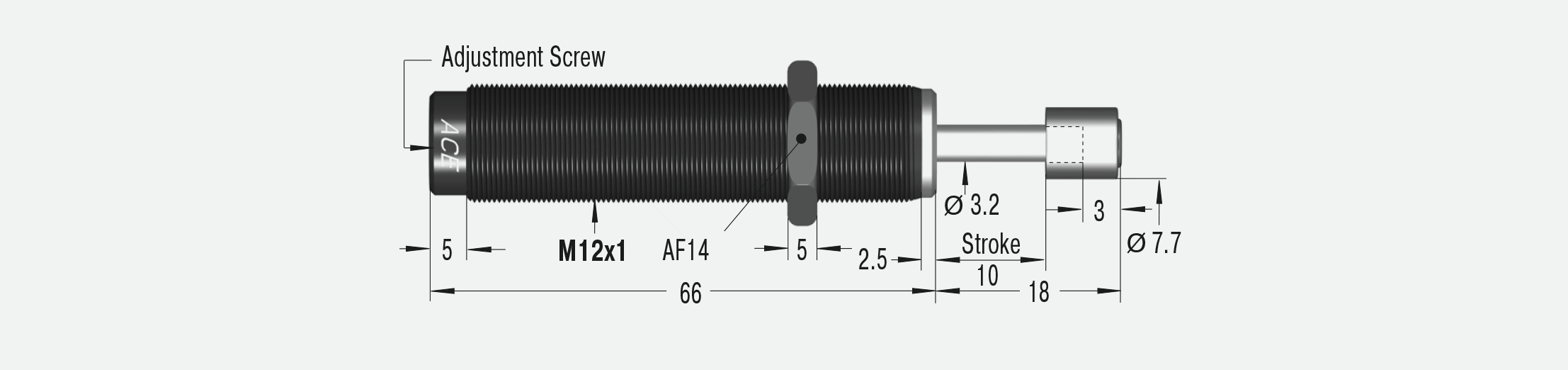

MA35EUM

Stepless adjustment

Adjustable

Energy capacity 4.0 Nm/cycle

Stroke 10.2 mm

All variations of these units are maintenance-free, ready-to-install machine elements and have an integrated positive stop. They provide the best service where application data changes, where the calculation parameters are not clear or where maximum flexibility in the possible usage is required.

Hydraulic feed controls with the designations FA, MA and MVC are especially used in handling modules or linear carriages and also for applications with changing usage data.

CAD Drawings

Product-Downloads

Family MA35EUM

| Operating & Mounting Instructions | 2.4 MB | 02/06/2022 | |

| English | |||

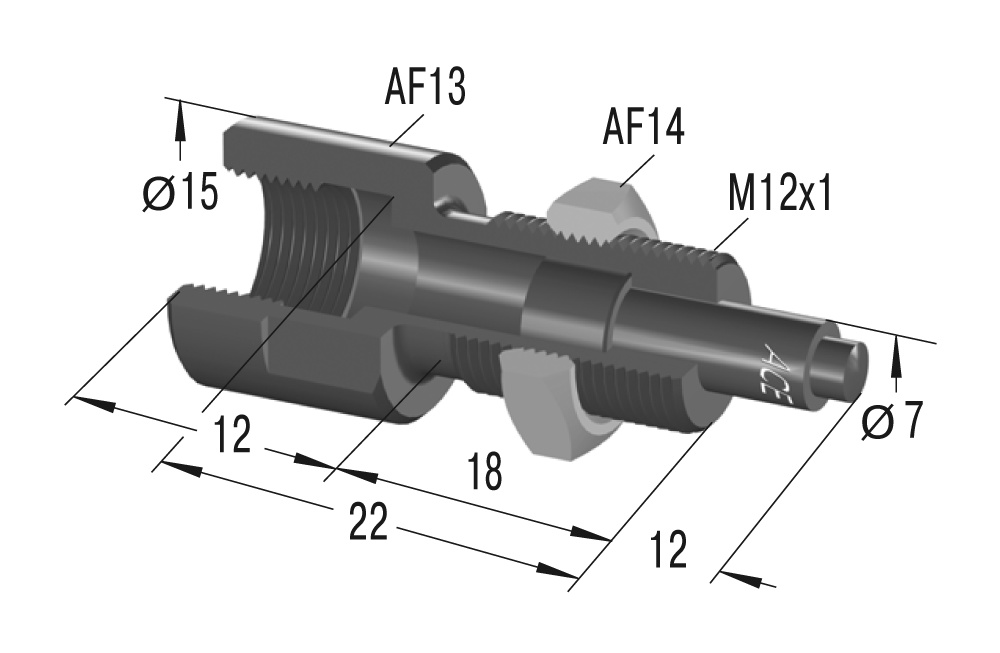

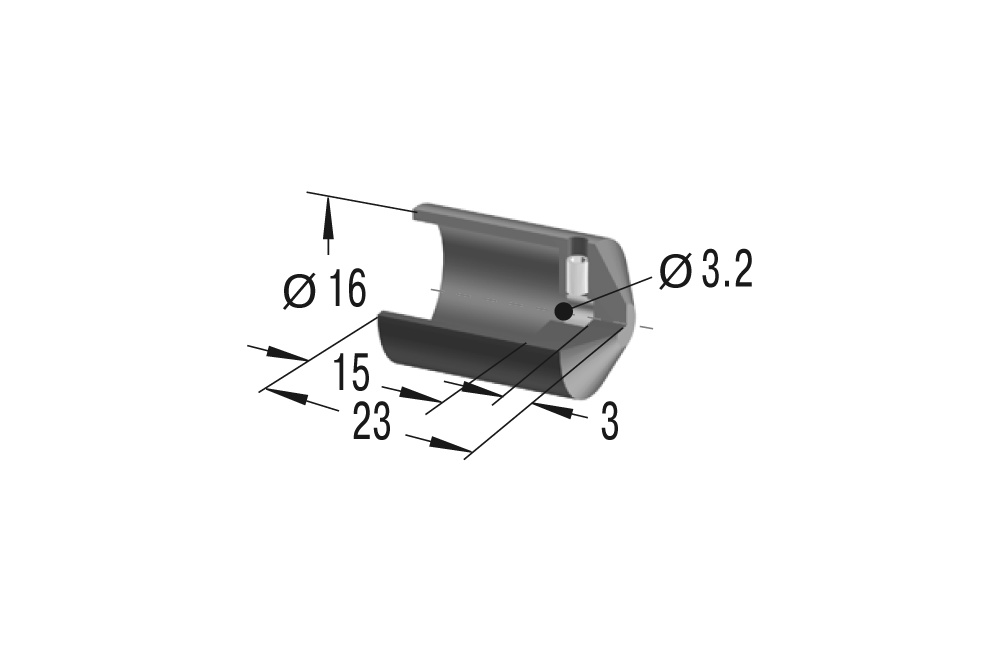

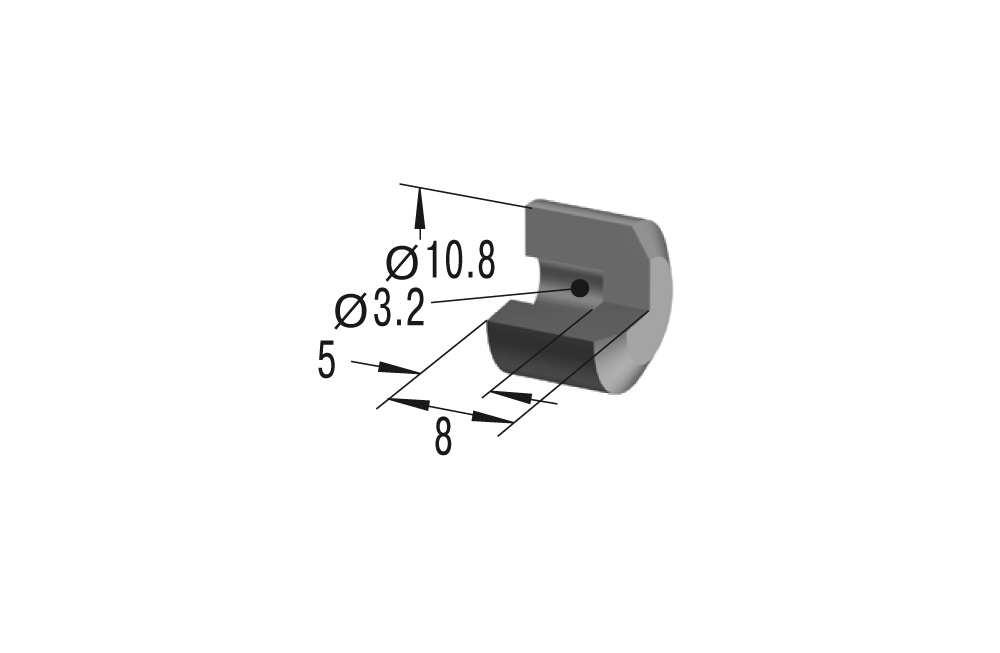

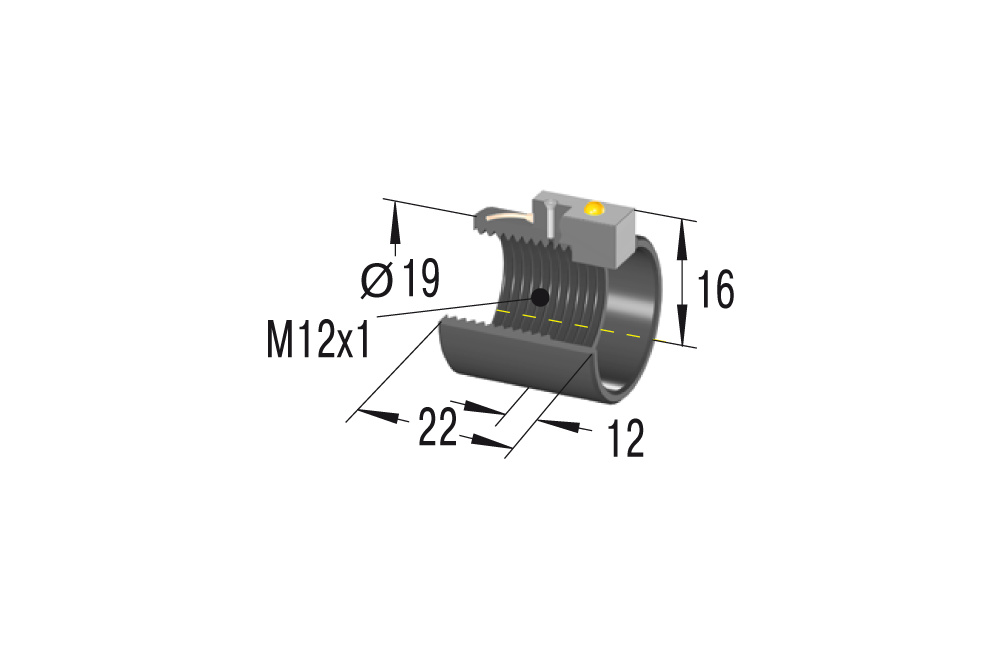

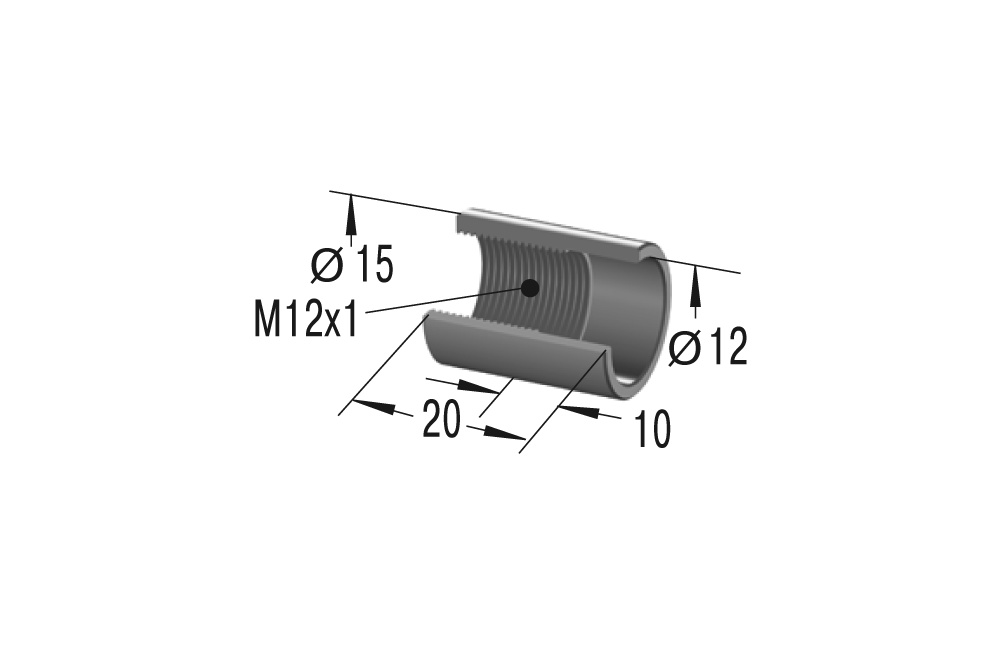

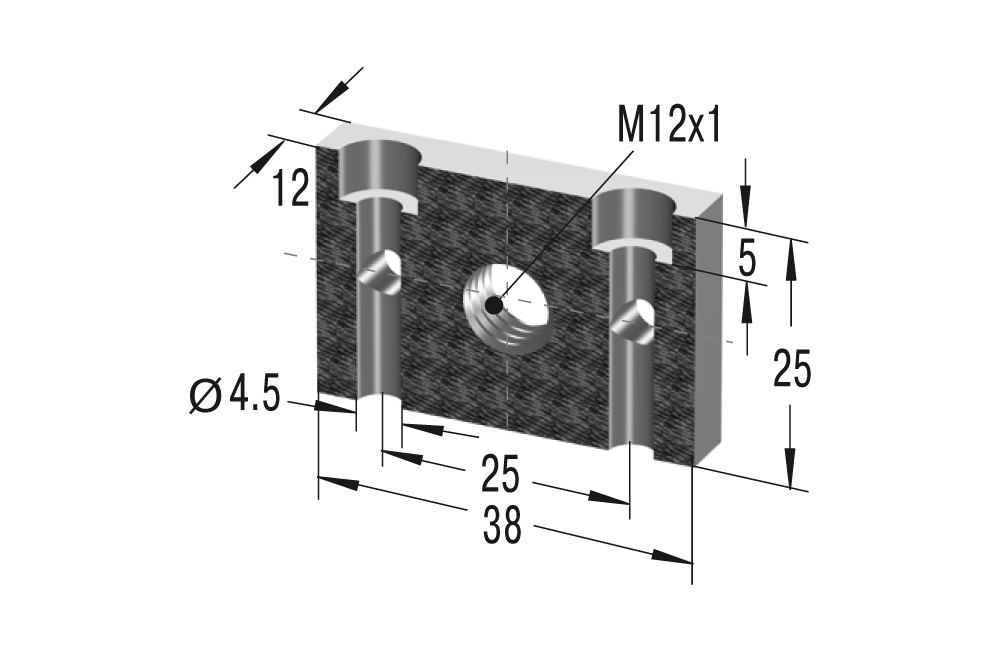

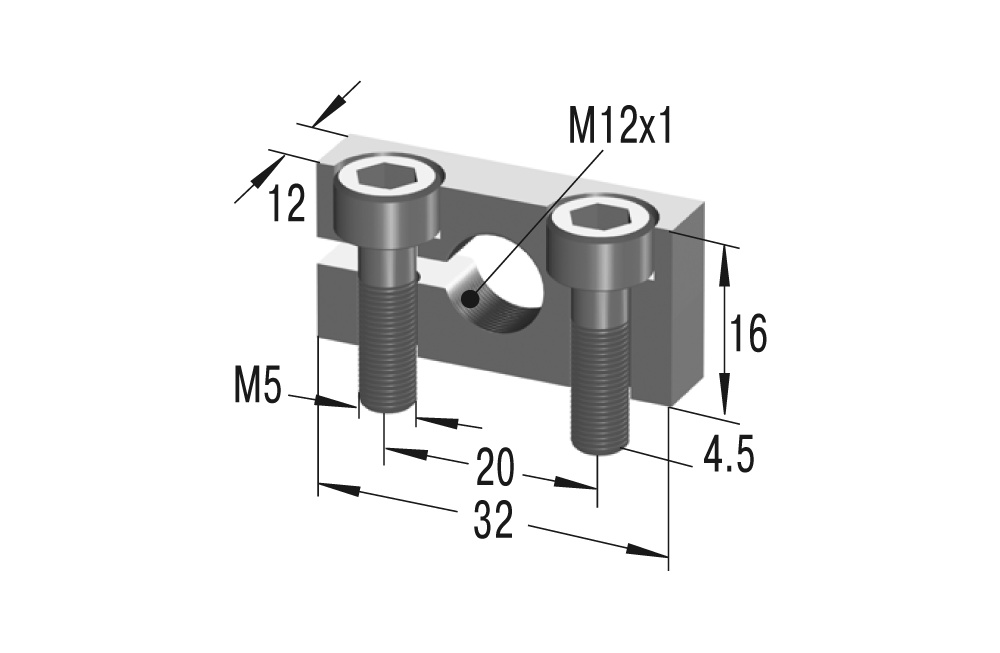

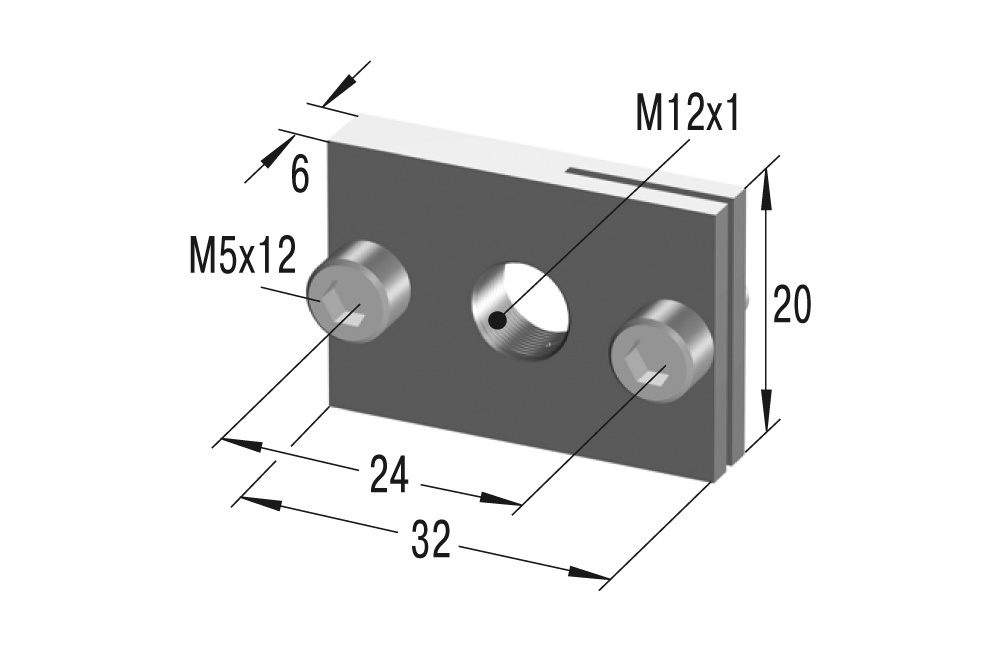

Dimensions

| Stroke | 10.2 mm |

Technical data

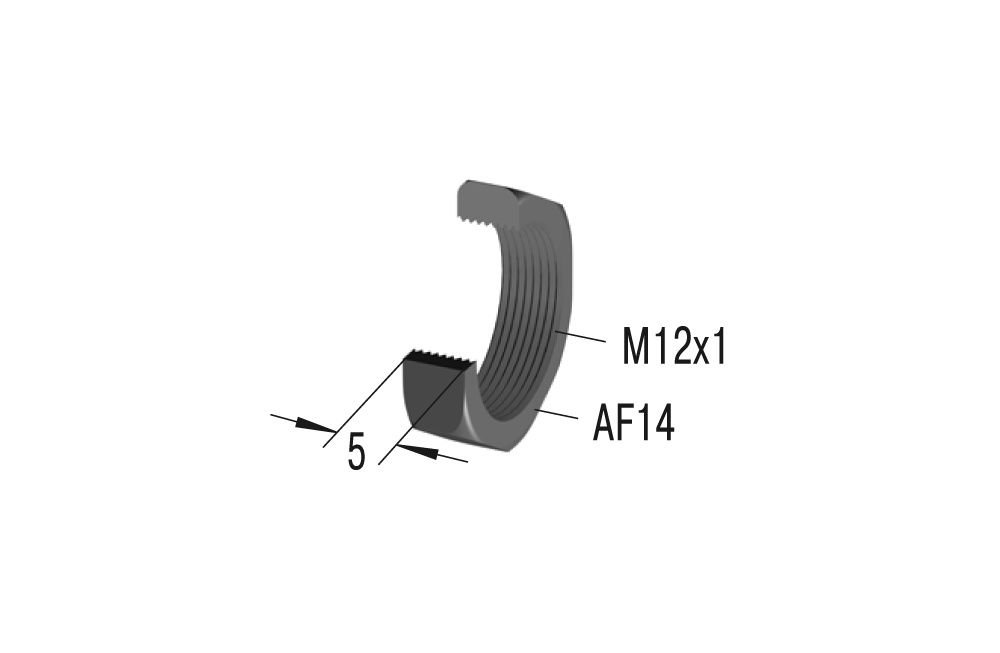

Energy capacity 4.0 Nm/cycle Energy capacity 6,000 Nm/h Effective weight min. 6.00 kg Effective weight max. 57 kg Return Force min. 5.0 N Return Force max. 11.0 N Return Time 0.2 s Side Load Angle max. 2 ° Impact velocity range At speeds of 0.3 m/s the maximum allowed energy is approx. 2 Nm. Where higher energies occur use a shock absorber for the initial impact. Avoid high impact velocities. Operating temperature range 0 °C to 66 °C Mounting in any position Positive stop Integrated Adjustment Hard impact at the start of stroke, adjust the ring towards 9 or PLUS. Hard impact at the end of stroke, adjust the ring towards 0 or MINUS. Material Outer body, Accessories: steel corrosion-resistant coating; Piston rod: hardened stainless steel Damping medium oil, temperature stable | NoteIf precise end position datum is required consider use of the stop collar type AH. Shock absorber is preset at delivery in a neutral position between hard and soft. Safety informationExternal materials in the surrounding area can attack the seal components and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. On requestNickel-plated or other special options available to special order. Models without rod end button. |

_FA_IMG_Single-01-cut-Labels_RGB-L_EN.jpg)

_FA_IMG_Single-01-cut_RGB-L.jpg)